How to Make Jelly Soap: A Complete Guide for OEM/ODM Clients

Introduction to Jelly Soap

Jelly soap has a playful appearance and a unique, gelatinous texture that makes it stand out. Jelly soap is a fun and exciting alternative to regular bar or liquid soap because it provides a new sensory experience. Thanks to its unique shape, bright colors, and personalizability, jelly soap has been a huge hit in the personal care industry around the world in recent years.

In an effort to stand out from the crowd and win over new consumers, a lot of companies are adding jelly soap to their lineups. Businesses looking to explore OEM or ODM solutions can find inspiration in jelly soap, which offers a unique chance to create marketable personal care items with a creative twist. This article will walk you through the fundamentals of manufacturing jelly soap, including how to personalize it and find opportunities to work with expert manufacturers as a partner.

Key Ingredients and Materials Used in Jelly Soap Manufacturing

The quality and effectiveness of jelly soap rely a lot on the components used to make it. The basic ingredients in jelly soap are usually a soft Soap Base and a gelling agent, such carrageenan or agar, which gives the soap its bouncy texture. Glycerin is typically added to soap because it helps keep skin moist, making it safe for all skin types.

To make jelly soap more appealing and useful, makers may include a number of safe, skin-friendly ingredients. Some of them are vitamins, essential oils, and plant extracts. Brands often utilize scents and colors to make their products look and smell good and fit with their market position.

All of the ingredients used to make OEM/ODM jelly soap must meet worldwide safety requirements and rules. This makes sure that the finished product is gentle, works well, and is safe to use every day, which meets the quality standards of both companies and customers.

The Jelly Soap Manufacturing Process: Step-by-Step

There are a number of exact and regulated stages involved in making jelly soap that must be followed in order to have the right texture and quality. The first step is usually to carefully prepare all of the raw components, including as the soap base, gelling agents, scents, and colorants. To make sure that every batch is the same and works as well as possible, the ingredients are carefully measured.

After that, the soap base and gelling agent are mixed together and heated to a certain temperature so that they may dissolve and mix well. When the mixture is the correct thickness, other components including colorants, essential oils, and moisturizers are added. Then, this mix is mixed slowly to make sure that all of the parts are evenly spread out.

The heated liquid is poured into molds that have different shapes and sizes, depending on what the client wants. After that, the molds are left alone to cool down so that the jelly soap may harden and set. The jelly soap is carefully taken out of the mold and checked for quality when it has cooled enough. The last step before packaging and shipping is to check the finished items one last time for quality. Any components that are not up to par are thrown away. This method makes sure that every piece of jelly soap is safe, looks good, and is easy to use.

Customization Options for OEM/ODM Jelly Soap

One of the best things about selecting OEM/ODM jelly soap manufacture is that you may customize it in many different ways. Jelly soap makers may make them fit the needs of each client in terms of branding and the market. You may start customizing by choosing the shapes and sizes. Jelly soaps can be shaped into almost any shape, from simple geometric forms to more complicated, themed patterns that fit with the brand's identity or seasonal promotions.

Another important part is being able to change the color and scent. Clients may pick from a wide range of bright colors and smells, from fruity and flowery to medicinal and exotic. Manufacturers can also add special components like natural extracts, exfoliants, or skin-conditioning agents to make bespoke products that meet the demands of certain customers.

Packaging is also very important for making products stand out. OEM/ODM partners may make custom packaging for you, such as private labeling, unique graphics, and materials that are good for the environment. This degree of customisation not only makes the product more appealing to customers, but it also helps firms stand out in a crowded market. This makes jelly soap a great addition to any personal care line.

Innovative Formulations and Trends in Jelly Soap

The jelly soap industry is always changing, and fresh ideas are important for getting new clients and keeping old ones. One of the most important trends is the move toward natural and organic products. More and more, people want jelly soaps that are manufactured with plant-based components, essential oils, and additions that are good for the environment. This is part of a larger trend toward clean and sustainable personal care products.

Adding functional additives is another area where new ideas are being used. Companies are making jelly soaps that do more than just clean. For example, they may moisturize, brighten, or kill germs. These extra features may help firms stand out from the competition and appeal to specialized customers. Also, companies may stay relevant and attractive to a wide range of customer tastes by using popular aromas like tropical fruits, herbal mixes, and seasonal scents.

Trends in design are also having an effect. Jelly soaps with several colors, layers, or glitter are becoming more popular because they look good and are easy to post on social media. OEM and ODM partners may assist customers create new jelly soap products that get people's attention and boost sales by keeping up with worldwide trends and always looking for fresh formulas.

Compliance, Safety, and Certification in Jelly Soap Production

To develop confidence with customers and end users, it is very important that jelly soap products fulfill the highest safety and regulatory criteria. The U.S. FDA, the European Union's Cosmetic Regulation (EC) No. 1223/2009, and appropriate Chinese requirements are only a few examples of rules that manufacturers must follow. Following these rules makes sure that the ingredients used are safe, have the right labels, and can be tracked.

Quality control and testing that are very strict are important aspects of the production process. It comprises microbiological testing, stability assessments, and skin compatibility evaluations to make sure the jelly soap is safe to use every day and stays good for as long as it is on the shelf. OEM/ODM clients usually get documents like Certificates of Analysis (COA), Material Safety Data Sheets (MSDS), and product safety studies to help them meet regulatory requirements.

The personal care business is likewise paying more and more attention to sustainability. Many companies now provide products that are good for the environment, such components that break down naturally, packaging that can be recycled, and formulas that don't hurt animals. Professional jelly soap makers help their clients establish businesses that are credible, trustworthy, and ready for the future by putting compliance, safety, and environmental responsibility first.

OEM/ODM Cooperation Process for Jelly Soap

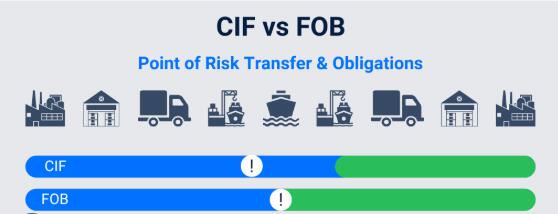

The OEM/ODM collaboration procedure is meant to make sure that clients have a smooth and quick experience from the first question to the delivery of the finished product. Usually, the process starts with a meeting to learn about the client's goals, product needs, and target market. In-depth talks address things like the desired compositions, forms, colors, scents, packaging alternatives, and following the rules.

The manufacturer makes samples for the client to look at after the parameters have been set. At this point, clients may see for themselves how good, well-looking, and useful the product is. Before going forward, feedback is collected and any changes that need to be done are made to make sure everyone is happy.

Both sides clarify the parameters of the order, such as the minimum order quantity (MOQ), price, and lead times, when the sample is approved. After that, the company starts mass manufacturing, making sure that quality control is tight at every step. When the jelly soaps are done, they are properly wrapped and sent out, with delivery scheduled on time to meet the client's needs.

OEM/ODM manufacturers make sure that every jelly soap project fulfills the client's standards for quality, customisation, and dependability by following a clear and cooperative workflow. This also helps them build long-term business relationships.

Why Partner with a Professional Jelly Soap Manufacturer?

Working with a professional jelly soap maker may be quite helpful for firms who want to add more products to their portfolio or break into new markets. Experienced manufacturers have a lot of technical knowledge, strong manufacturing capacities, and complete quality management systems that make sure that all of their products are always of high quality and meet all of the necessary rules.

Brands can quickly create and launch unique jelly soap products that fit their market strategy by using the invention and customisation skills of a specialist manufacturer. Professional partners also help a lot during the development phase by helping with things like optimizing the formulation, designing the packaging, writing regulatory documents, and coordinating logistics.

Also, dealing with a reliable OEM/ODM supplier lowers risk, speeds up time to market, and lets customers focus on creating their brand and marketing. Many successful partnerships have led to the invention of jelly soap products that sell well and the expansion of the business over time. In the end, picking the appropriate manufacturing partner is the most important thing you can do to make sure your personal care products are of the highest quality, your business runs smoothly, and you stay ahead of the competition.

Frequently Asked Questions (FAQs) about Jelly Soap OEM/ODM

Q: How many OEM/ODM jelly soap orders do you need to make?

A: The minimum order quantity (MOQ) changes based on the maker and how much customisation is needed. Most of the time, MOQs are between a few thousand and tens of thousands of items per order.

Q: How long does it take to make and sell a personalized jelly soap?

A: The usual timetable is sample development (1–2 weeks), client approval, and mass manufacturing (3–6 weeks). The overall lead time will depend on how complicated the order is and how much production space is available.

Q: Is it possible to change the recipe to work better for certain skin types or purposes?

A: Yes, A. Professional producers may make formulae that are perfect for those with sensitive skin, need more moisture, have antibacterial properties, or use only natural or organic components.

Q: What kinds of certifications may jelly soap products get?

A: Most of the time, manufacturers can give you paperwork like MSDS, COA, and certificates that show they are following FDA, EU, or other market rules.

Q: Can you make different forms, colors, and packaging?

A: Yes, of course. OEM/ODM services include unique molds, a wide range of colors and scents, and custom packaging options that meet your branding and marketing objectives.

Most manufacturers are ready to provide you thorough advice and help you through the process if you have more questions or need a specialized solution.